OUR BRANDING

Colourflex

Debossing

Digital-Packaging-Print

Digital-Label

Colourflex

Debossing

Digital-Packaging-Print

Imitation-Etch

Direct-Digital

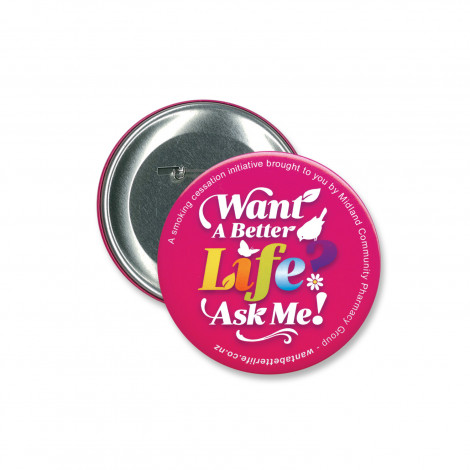

Digital-Print

Embroidery

Digital-Label

Laser-Engraving

Pad-Print

Resin-Coated-Finish

Rotary-Digital-Print

Rotary-Screen-Print

Silicone-Digital-Print

Screen-Print

Sublimation-Print-Dye

PAD PRINTING

Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. It is one of the most popular and affordable ways of branding promotional products due to its ability to reproduce images on uneven or curved products and print multiple colours in a single pass.

Advantages

-

Ideal for printing on curved or uneven products.

-

Prints sharp, clean images with detail as fine as 0.4mm, minimum text size is 5pt.

-

Close PMS matches are possible on white or light-coloured products.

-

Metallic gold and silver ink are available.

-

Can offer a white under base for the darker products that require it.

-

Many products can print up to 6 colours with tight multi-colour registration.

Limitations

-

Halftones cannot be consistently reproduced.

-

Unable to print variable data such as individual naming.

-

Close PMS matches are more difficult on darker products and will only be approximate. In these instances, a white base will create a better print.

-

Some pad print inks require a curing period before the product can be shipped.

-

Each colour requires its own setup charge.

-

Neon/fluorescent colours are not available.

Artwork Requirements

-

Artwork must be supplied in a vector editable format.

-

Fonts are advised to be converted to outlines/objects to avoid font conflicts.

IMITATION ETCH

Imitation etch is a special pad printing ink used for producing an etch-like effect on glass products.

Advantages

-

Much more affordable than real etching.

-

Can brand curved or uneven products.

-

Produces a subtle finish with a higher perceived value that looks like etching.

Limitations

-

Halftones cannot be consistently reproduced.

-

The size of branding areas is limited on curved surfaces.

-

Requires a curing period before the product can be shipped.

-

Unable to print variable data.

Artwork Requirements

-

Artwork must be supplied in a vector editable format.

-

Fonts are advised to be converted to outlines/objects to avoid font conflicts.

DIGITAL PRINT

This production method is used for printing media such as paper, vinyl and magnetic material used in the manufacture of labels, badges, and fridge magnets etc. This printing process uses CMYK values.

Advantages

-

Ideal for producing full colour, complex images with gradients.

-

Variable data including individual names is available on select products.

-

Only one set up charge is required regardless of the number of print colours.

-

Dries instantly so products can be shipped immediately.

-

Select products can be cut to custom shapes.

-

Edge-to-edge branding can be achieved on certain products.

Limitations

-

Metallic and neon/fluorescent colours are not available.

-

White print cannot be produced on kraft, clear, silver or gold stock.

-

Cannot print on dark coloured substrates as white ink cannot be printed underneath the artwork

Artwork Requirements

-

Artwork can be supplied in either vector or bitmap format.

-

Supplied bitmaps must be higher than 300DPI resolution at the actual print size.

-

A 3mm bleed should be added to the artwork if it bleeds off the product.